Tags:

@Wake@hexbear.net @raven@hexbear.net @ForgetPrimacy@lemmygrad.ml @macerated_baby_presidents@hexbear.net @sharedburdens@hexbear.net @Edie@hexbear.net @BountifulEggnog@hexbear.net @YearOfTheCommieDesktop@hexbear.net @Erika3sis@hexbear.net @CarbonScored@hexbear.net @frankfurt_schoolgirl@hexbear.net @oscardejarjayes@hexbear.net @crosswind@hexbear.net @lilypad@hexbear.net @OurToothbrush@lemmy.ml @tartan@lemmy.ml @AernaLingus@hexbear.net @SnAgCu@hexbear.net @naevaTheRat@lemmy.dbzer0.com @lapis@hexbear.net @Hurvitz@hexbear.net @jwsmrz@hexbear.net @MarxGuns@hexbear.net @AbbysMuscles@hexbear.net @pooh@hexbear.net @Chronicon@hexbear.net @AmaryllisBlues@hexbear.net @tactical_trans_karen@hexbear.net @TheDoctor@hexbear.net @aphir@hexbear.net @RussianEngineer@hexbear.net @the_itsb@hexbear.net @DaPorkchop_@lemmy.ml @Ruthalas@infosec.pub @Llituro@hexbear.net @Awoo@hexbear.net @Kiagz@hexbear.net

If you'd like to be on the tag list, or if you're on the tag list and would like to be removed, let me know here or in a DM!

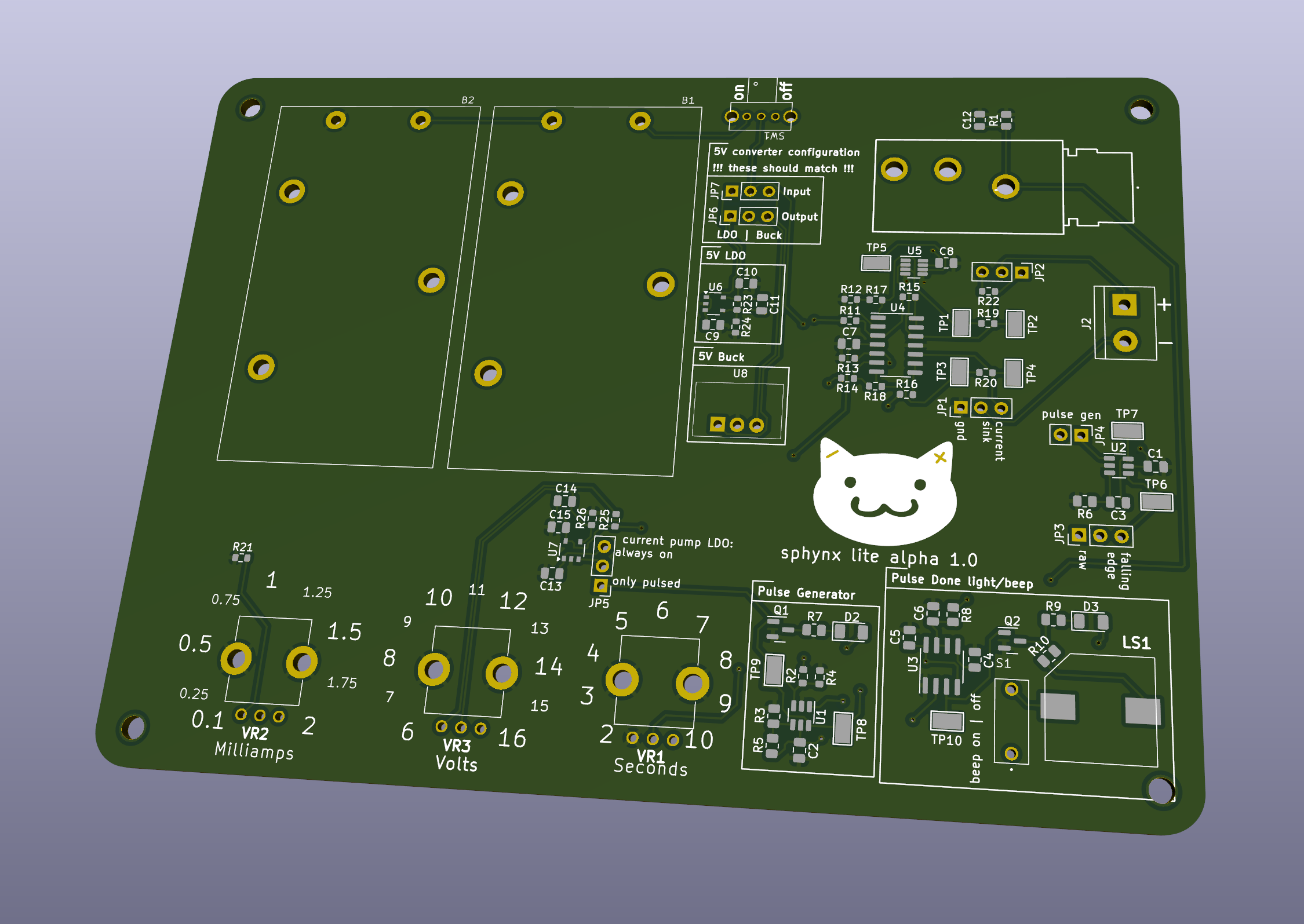

honestly the process is so beautiful i wouldn't trade it for the world

that said I'd love a little break from time to time 🥲